Mastering the “Last Mile”: Why the Right Tool is Crucial for Your Watch Band Business

As professionals in the watch and accessory industry, we understand that the customer journey doesn’t end at the point of sale. For metal watch bands, in particular, the post-purchase experience of adjusting the band to fit is a critical touchpoint. While seemingly minor, the tool provided or recommended for this task – the watch link removal tool – carries significant weight, impacting customer satisfaction, operational costs, and ultimately, your brand’s reputation.

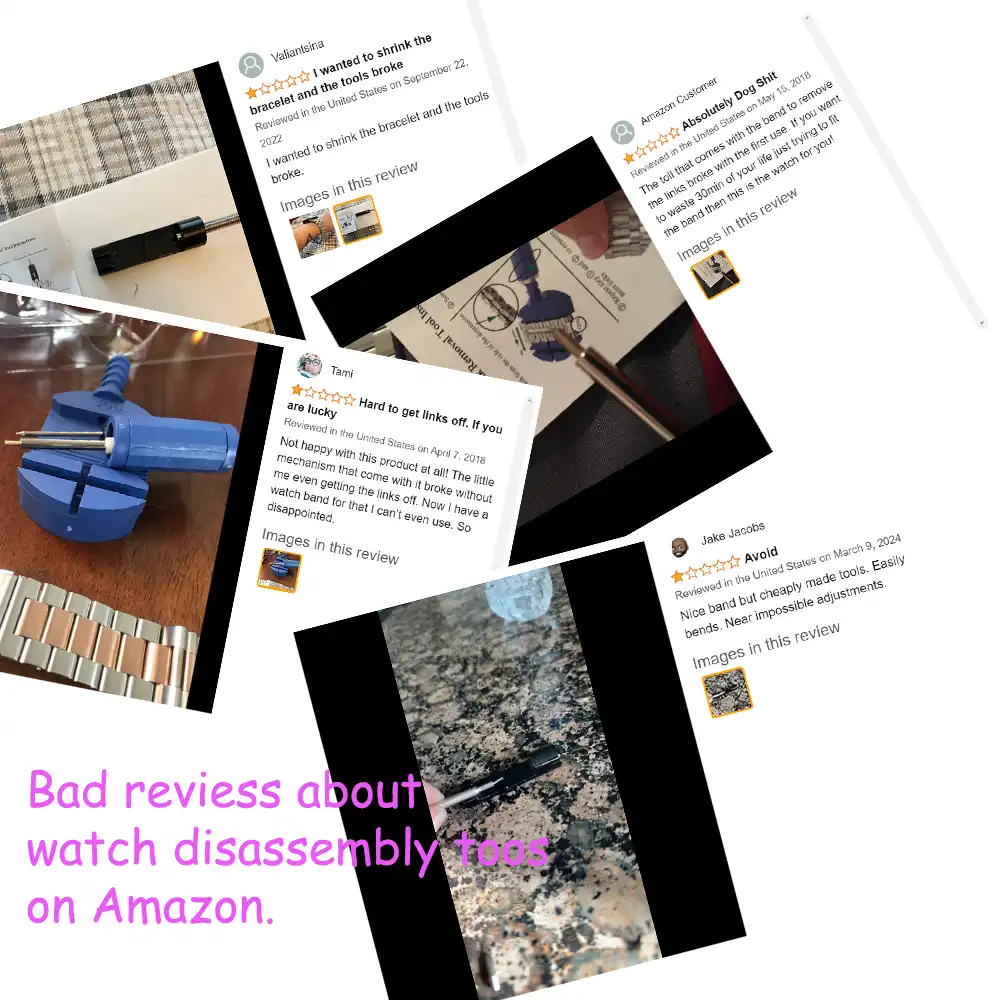

The reality, starkly visible across e-commerce platforms like Amazon, is that inadequate adjustment tools are a frequent source of customer frustration. Sellers, often driven by tight cost controls, may bundle tools that are simply not up to the task. The consequence? Tools breaking mid-use, customers unable to wear their new purchase, and a cascade of negative outcomes for your business.

This isn’t just about minor inconvenience; it translates directly into tangible business challenges:

- Elevated Return Rates: Failed adjustments are a prime driver for returns, incurring costs in reverse logistics, reprocessing, and lost revenue.

- Negative Reviews & Ratings: Frustrated customers voice their displeasure publicly, damaging product ratings, deterring future buyers, and impacting your brand perception.

- Customer Churn: A poor post-purchase experience erodes trust and significantly reduces the likelihood of repeat business.

- Increased Customer Service Load: Fielding inquiries about tool usage, breakages, and adjustment difficulties consumes valuable support resources.

Therefore, for watch band sellers and brands, strategically addressing the band adjustment experience, starting with the choice of the watch link removal tool, is not an incidental detail – it’s a fundamental aspect of customer care and business optimization. This article delves into five critical factors every seller must consider when selecting or recommending these essential tools, transforming a potential pitfall into a competitive advantage.

Selecting the Right Watch Link Removal Tool: 5 Critical Factors for Sellers

Whether you’re bundling a tool with every band or recommending one to your customers, the decision demands more than a cursory glance at the unit price. A truly “suitable” tool balances functionality, cost, and brand alignment. Based on extensive industry observation, here are the five pivotal elements sellers must evaluate:

1.Durability & Functional Integrity: Ensuring Success, Preventing Failure

The pins holding metal watch band links together, especially on new products, can be exceptionally tight, requiring significant ejection force. A tool lacking structural integrity – perhaps made from inferior plastic or equipped with a soft, non-hardened steel pin – is prone to bending, breaking, or failing before the pin is successfully removed.

The Repercussion? A broken tool, an unadjusted band, and an extremely dissatisfied customer. This scenario almost guarantees a product return, a negative review, or both.

Seller’s Strategic Imperative: Prioritize strength and durability in your tool selection. Ensure the tool body is robust and, critically, that the pin is made from hardened steel capable of withstanding the required force. Investing slightly more in a tool that reliably performs its function prevents far more costly downstream issues related to returns processing and reputation management. This is about ensuring functional integrity under typical use-case stress.

2.Compact Size & Form Factor: Optimizing for Logistics and Packaging

Many sellers choose to bundle the removal tool directly with the watch band. In this context, the tool’s physical volume and dimensions become a practical constraint and a cost factor.

- Packaging Compatibility: The tool must fit efficiently within your existing or planned product packaging without necessitating costly redesigns or larger boxes.

- Logistics Costs: Larger and heavier packages incur higher shipping costs, particularly for international sellers operating on platforms like Amazon where dimensional weight is a factor. This directly impacts profit margins.

Seller’s Strategic Imperative: Seek tools that achieve a compact form factor suitable for cost-effective packaging and shipping, without compromising the essential durability outlined in Point 1. It requires a deliberate balance between logistical efficiency and the tool’s functional robustness. Overly large tools inflate costs, while excessively miniaturized, weak tools lead to failure.

3. Material & Appearance: Aligning with Brand Positioning and Perceived Value

The choice of material for a link removal tool influences not only its durability and tactile feel but also communicates subtle messages about your brand and the perceived value of your product.

- Material Considerations:

- Plastic: Offers the lowest cost and weight but often sacrifices durability and can project a “cheap” image. May be acceptable only for the most budget-sensitive product tiers.

- Metal – Zinc/Aluminum Alloy: Provides a good equilibrium between cost, durability, and a more substantial feel. A common and often effective choice, allowing for various finishes.

- Metal – Stainless Steel: Delivers superior durability and a premium tactile experience but comes at a higher cost. Best suited for complementing mid-range to high-end watches and bands, enhancing overall perceived value.

- Aesthetic Cohesion: The tool’s color, finish (e.g., matte, brushed, polished), and overall design language should ideally complement the style of the watch bands you sell and align with your brand identity. A mismatch – like a rudimentary plastic tool accompanying a luxury band – creates brand dissonance.

Seller’s Strategic Imperative: Select tool materials and aesthetics that are congruent with your target market segment, product price points, and desired brand positioning. Ensure the accessory enhances, or at least does not detract from, the perceived quality and value of your core offering.

4.Band Protection Features: Mitigating Risk of Cosmetic Damage

Metal watch bands, particularly those with fine surface finishes like high polish, intricate brushing, or PVD coatings, are vulnerable to scratches and scuffs during the adjustment process. The points of contact between the tool and the band are high-risk areas.

- Tool Design Considerations:

- Ensure surfaces where the band rests (the tool base or platform) are smooth and free of burrs or sharp edges.

- Look for features like adjustable height or varying groove depths to properly support different band thicknesses, preventing instability and scraping.

- While less common in basic bundled tools, features like non-marring contact points (e.g., rubberized pads) offer superior scratch prevention.

- Customer Guidance: Even with a well-designed tool, providing simple instructions (e.g., via an insert card) advising customers on careful handling – perhaps suggesting the use of protective tape – is a prudent measure.

Seller’s Strategic Imperative: Opt for tools designed with band protection in mind. Minimizing the risk of cosmetic damage during adjustment preserves the product’s aesthetic value and reduces complaints related to scratching. This demonstrates attention to detail and respect for the customer’s purchase.

5.Cost-Effectiveness: Assessing Total Cost of Impact Beyond Unit Price

Unquestionably, cost control is a major driver in sourcing decisions, especially for high-volume sellers dealing with accessories often perceived as low-use items.

- Redefining ‘Cost’: It’s crucial to look beyond the purchase price per unit. The true cost of a tool includes the potential downstream expenses associated with a substandard one: the operational cost of processing returns, the revenue impact of negative reviews, damage to brand reputation, and increased customer service overhead. This is the “Cost of Poor Quality” (COPQ).

- Striving for ‘Value’: The objective should be optimal value for money or cost-effectiveness, not merely the lowest possible price. This means finding a tool within an acceptable budget that reliably performs its function, minimizes the risk of band damage, and doesn’t actively detract from the customer experience.

Seller’s Strategic Imperative: When making procurement decisions, evaluate the tool’s total cost of impact. A tool that costs slightly more upfront (e.g., $0.50 vs. $0.20) but functions reliably and avoids causing damage might save significantly more in the long run by reducing returns and protecting brand equity. Adopt a value-driven sourcing approach.

Conclusion: Elevating Customer Experience and Sales Through Thoughtful Tool Selection

In conclusion, the selection and provision of a suitable watch link removal tool represent far more than a logistical footnote for watch band sellers and brands. It’s a strategic decision impacting customer satisfaction, operational efficiency, brand image, and ultimately, your bottom line.

By carefully considering the five key factors – Durability & Functional Integrity, Compact Size & Logistics, Material & Appearance, Band Protection, and overall Cost-Effectiveness – you can move beyond a purely cost-minimization approach. Investing appropriately in this seemingly small accessory demonstrates a commitment to the complete customer experience.

As industry professionals, let’s recognize that mastering this “last mile” of the customer journey, ensuring buyers can easily and safely adjust their new purchase, is a powerful lever for building loyalty, earning positive reviews, reducing costly problems, and driving sustainable sales growth. We encourage you to critically evaluate your current tool strategy against these benchmarks.

Tags: Metal Watch Bands, Watch Link Removal Tool

-1.png)

One thought on “Watch Link Removal Tool: 5 Things Sellers Need to Know”

Thank you for this incredibly insightful guide on table-splitting tools! As someone new to this, your breakdown of safety standards, compatibility checks, and scenario-based recommendations saved me from countless potential pitfalls. Your advice about ‘not blindly chasing feature quantity’ was a game-changer — I’ve already started using the removal tool you suggested, and it’s boosted my workflow efficiency tremendously. Looking forward to more of your hands-on reviews! Keep up the fantastic work!