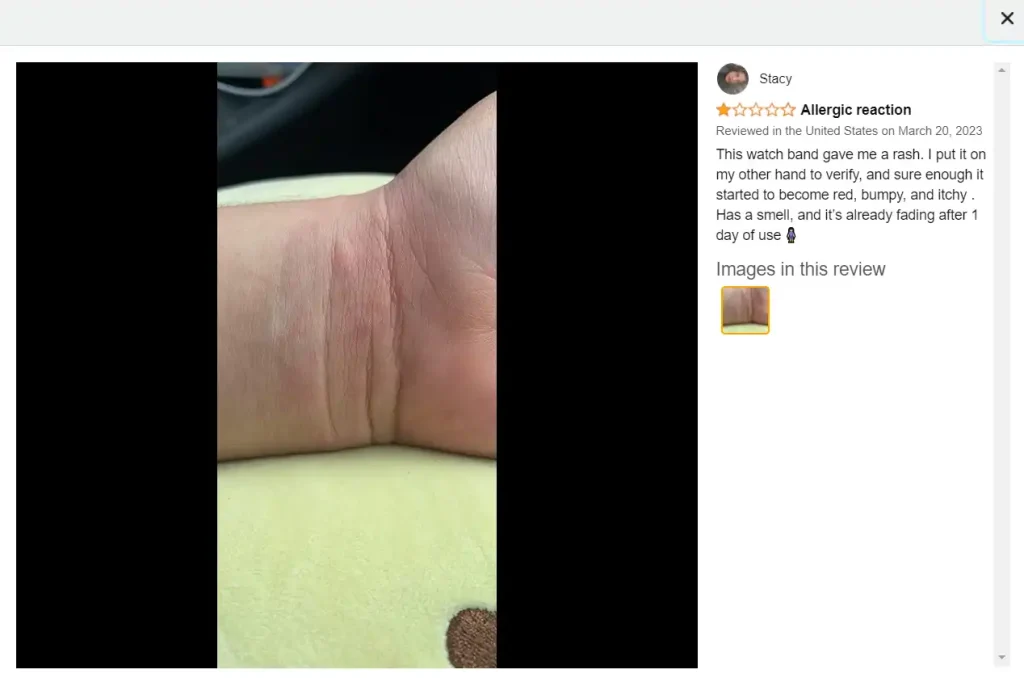

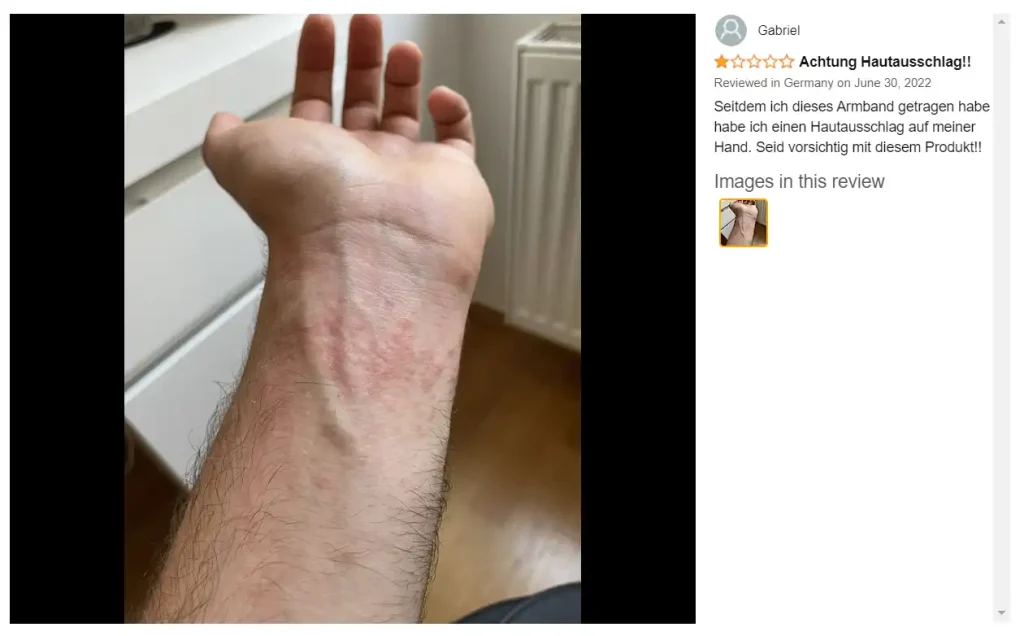

Wearing a watch is a daily habit for many, but for some, it can lead to uncomfortable skin reactions, commonly referred to as a watch band rash.. While stainless steel has long been a known culprit, it’s becoming increasingly clear that other popular materials, like silicone, can also trigger irritation and allergies. Understanding the root causes, whether from the watchband’s material or its components, is key to choosing a comfortable and safe accessory.

Common Culprits:Why Do Metal WatchBand Cause Allergies?

Stainless steel, widely chosen for its durability and aesthetic appeal, can unfortunately be a source of skin irritation for sensitive individuals. The primary cause of allergic reactions to stainless steel is often nickel, a metal commonly used in its alloys to enhance malleability and shine. For those with nickel sensitivity, even minute amounts leaching from the watchband can cause contact dermatitis, manifesting as itching, redness, rashes, and general discomfort.

Several factors can exacerbate these metal-induced reactions:

1.Continuous Contact:

Prolonged skin contact, especially over extended periods, increases exposure to potential allergens.

2.Sweat and Moisture:

Trapped sweat and moisture underneath the band create a warm, damp environment that can accelerate the corrosion process of the metal, potentially increasing the release of nickel ions onto the skin. This environment also weakens the skin’s natural barrier, making it more susceptible to irritation.

Unmasking Silicone Watchband Irritation:More Than Meets the Eye

Silicone watchbands are celebrated for their flexibility, durability, and often, their hypoallergenic reputation. Composed of synthetic polymers containing silicon, oxygen, carbon, and hydrogen atoms, silicone is generally considered to have low toxicity. However, our investigations and industry observations reveal that silicone watchbands can indeed lead to skin irritations and allergic reactions, much like their metal counterparts.

The primary reasons for irritation from silicone watchbands are multifaceted:

Material-Related Sensitivities

While silicone itself is generally well-tolerated, certain individuals may react to specific components or additives used during the manufacturing process. These can include:

- Production Additives: Substances like sulfur or organic peroxides, vital for curing silicone, can sometimes act as allergens for highly sensitive individuals.

- Colorants and Dyes: Chemicals used to achieve the desired color of the silicone band can also trigger inflammatory responses upon prolonged skin contact.

- Cross-Reactivity: In rare cases, individuals with a latex allergy might experience cross-reactivity with silicone due to similar protein structures or manufacturing processes.

The Role of Moisture and Hygiene

Similar to metal bands, the environment created by wearing a silicone watchband plays a significant role in skin irritation:

- Trapped Sweat and Moisture: Silicone’s non-porous nature can trap sweat and moisture against the skin. This creates a perpetually moist environment, which softens the skin and makes it more vulnerable to irritation.

- Bacterial Growth: A warm, moist environment is an ideal breeding ground for bacteria. This can lead to bacterial infections such as folliculitis (inflammation of hair follicles) or various forms of dermatitis, causing itchy, red, and inflamed skin.

- Chemical Interactions: Sweat contains various salts and chemicals that can potentially interact with components in the silicone, leading to further irritation.

The Hidden Culprit:Metal Buckles

Often overlooked, the metal buckles, clasps, or pins on silicone watchbands are a common source of allergic reactions. These components frequently contain nickel or other allergenic metals, mirroring the issues seen with full metal watchbands. Reactions may specifically appear where the metal buckle touches the skin, even if the silicone band itself is not the primary irritant.

The Impact of Fit

The fit of any watchband, regardless of material, is crucial for preventing irritation:

- Tightness and Friction: A watchband that is too tight can cause excessive friction against the skin, leading to chafing, disruption of the skin’s protective barrier, and subsequent irritation and inflammation. It also exacerbates moisture trapping.

The B2B Imperative:Material Standards and Certifications

For B2B clients, ensuring the health and safety of end-users is not just good practice; it’s essential for brand reputation and minimizing costly returns. This is where the quality and composition of the stainless steel become critically important.

1.Why Standard Stainless Steel Might Not Be Enough

Many generic Metal WatchBand may contain higher levels of nickel or may not be manufactured to control nickel release effectively. This can be a hidden liability for businesses.

2.The Gold Standard: 316L and Other Hypoallergenic Stainless Steel Grades

Opting for higher-grade stainless steel, such as 316L (often referred to as surgical grade) or 430L stainless steel, is a crucial step. These alloys are specifically formulated to have significantly lower nickel content and superior corrosion resistance. This dramatically reduces the risk of allergic reactions.

- Nickel Release Standards:

It’s vital to source watchbands that comply with established nickel-release standards, such as the EU REACH regulation, which limits nickel release to less than 0.5 micrograms per square centimeter per week (µg/cm²/week) for items in direct and prolonged contact with the skin. Partnering with suppliers who can provide certification of compliance is key.

The Business Benefit of Prioritizing Quality Materials

Investing in watchbands made from certified, low-nickel, or hypoallergenic materials translates directly to:

- Reduced customer complaints and returns related to allergies.

- Enhanced brand image and customer trust.

- Increased customer loyalty and positive reviews.

- Compliance with international safety standards, opening up broader market access.

Solutions for Your Customers: Hypoallergenic Alternatives & Best Practices

Beyond choosing superior stainless steel, offering a range of solutions can cater to even the most sensitive individuals:

Promoting Low-Nickel and Certified Stainless Steel Options

Clearly label and promote watchbands made from 316L or other certified low-nickel stainless steel. Educate your clients about the benefits.

Exploring Other Hypoallergenic Materials

For users with extreme sensitivities, consider offering alternatives such as:

- Titanium: Highly biocompatible and lightweight.

- Ceramic: Sleek, durable, and inert.

- Surgical Grade Stainless Steel (316L or 430L): As emphasized, a premier choice.

- Precious Metals (e.g., Gold, Platinum): Often well-tolerated, though cost is a factor.

Advising End-Users on Wear and Care

While material is key, advising end-users to:

- Limit very prolonged, uninterrupted wear if they have known mild sensitivities.

- Keep the wrist and watchband clean and dry.

- Loosen the band slightly if moisture builds up. Can also contribute to a better experience.

Partner with Heibor: Your Source for Quality and Safety in Watchbands

At Heibor, we understand the critical importance of material integrity in watch components. We specialize in providing high-quality Metal watchband, including options crafted from certified 316L stainless steel and other hypoallergenic materials designed to meet stringent international standards.

Why Choose Heibor for Your B2B Watchband Needs?

- Material Expertise: Deep knowledge of metal properties and their impact on wearability.

- Quality Assurance: Commitment to sourcing and supplying certified materials.

- B2B Focus: Understanding the needs of watch manufacturers and distributors for reliable, compliant components.

- Custom Solutions: Ability to work with you on OEM/ODM projects to meet specific material and design requirements.

Elevate Your Brand with Hypoallergenic Watchband Solutions

Don’t let material quality be an afterthought. By prioritizing certified hypoallergenic stainless steel and other skin-friendly materials for your watchbands, you protect your customers, enhance your brand’s reputation, and build a stronger business.

-1.png)